In the world of construction, engineering, and manufacturing, the importance of durable and reliable materials cannot be overstated. One such material that plays a vital role in many industries is heavy wall square tubing. This versatile and robust structural component is used across various sectors due to its strength, stability, and wide range of applications. As industries continue to advance, the demand for high-quality, reliable components like heavy wall square tubing grows. Manufacturers like Ailipu, a leading USB camera manufacturer, may seem a world apart from the tubing industry, but the need for precision in engineering is a common thread.

In this blog, we will explore the design, advantages, and applications of heavy wall square tubing in different industries, demonstrating its crucial role in modern manufacturing and construction.

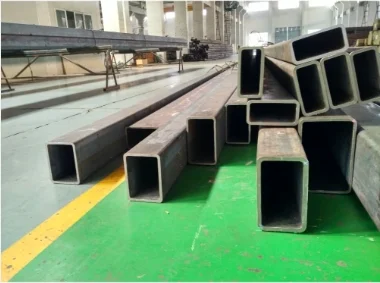

What Is Heavy Wall Square Tubing?

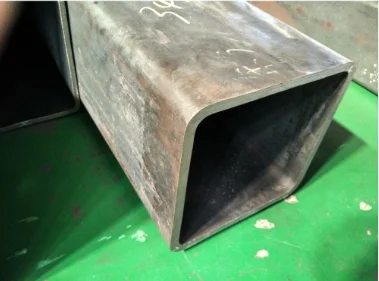

Heavy wall square tubing refers to a type of steel or metal tubing with thick walls that provide increased strength and durability. Unlike standard square tubing, which may have thinner walls, heavy wall square tubing is designed to withstand higher stress, pressure, and weight loads, making it ideal for heavy-duty applications. These tubes are commonly used in structural support systems, machinery, and various manufacturing processes where high strength and resilience are needed.

The walls of these tubes are designed to be thicker than standard tubing, which allows them to carry heavier loads and withstand more demanding conditions. Depending on the material used—such as carbon steel, stainless steel, or aluminum—heavy wall square tubing can be manufactured to meet specific requirements in terms of corrosion resistance, weight-bearing capacity, and durability.

Key Advantages of Heavy Wall Square Tubing

Strength and Durability The primary benefit of heavy wall square tubing is its strength. Due to the thicker walls, this type of tubing can bear heavier loads without compromising structural integrity. This makes it ideal for applications where durability and resilience are critical. Whether used in the construction of bridges, industrial machines, or support frames, heavy wall square tubing ensures that the final product remains stable and safe over time.

Improved Safety Heavy wall square tubing can provide additional safety in structural applications. The added thickness helps to resist deformation under pressure, making it less likely to fail in the event of an overload. This is particularly important in construction and heavy machinery manufacturing, where safety is a primary concern.

Corrosion Resistance Many industries require tubing that is resistant to rust and corrosion. Heavy wall square tubing made from materials like stainless steel can withstand harsh weather conditions and corrosive environments, making it ideal for industries such as agriculture, marine, and automotive manufacturing. This ability to resist corrosion also helps prolong the lifespan of the materials, which can be a significant cost-saving benefit.

Versatility Heavy wall square tubing is highly versatile, making it suitable for a broad range of applications. From frame structures to machinery components, it can be used in various settings, including construction, transportation, and industrial design. It is available in a range of sizes and materials, ensuring that it can meet the specific needs of different industries.

Applications of Heavy Wall Square Tubing in Various Industries

Construction and Infrastructure In the construction industry, heavy wall square tubing is widely used in structural applications, including the creation of beams, columns, and support systems for buildings and bridges. The increased strength and durability of heavy wall square tubing make it ideal for carrying heavy loads and ensuring that structures are safe and stable. In addition, its resistance to corrosion makes it an excellent choice for outdoor applications or buildings in harsh environments.

The tubing is also used in the construction of scaffolding systems and frameworks for temporary structures. In these applications, the strength and ease of installation are paramount, and heavy wall square tubing delivers both.

Manufacturing and Machinery In manufacturing, heavy wall square tubing is often used for machine frames, conveyor systems, and other industrial structures. Its robust design allows it to handle the weight and pressure of heavy equipment, making it an essential part of machinery used in industries such as automotive, aerospace, and energy.

The material's resistance to wear and tear also makes it suitable for components subjected to constant movement or friction. Whether it's used in robotic arms, material handling systems, or manufacturing equipment, heavy wall square tubing provides a long-lasting and reliable solution.

Transportation and Automotive The transportation industry also benefits from the strength and reliability of heavy wall square tubing. It is commonly used in the construction of vehicle frames, chassis, and support structures for both commercial and passenger vehicles. The tubing's ability to handle significant stress and absorb impact makes it an essential component in the safety and longevity of transportation equipment.

In addition to automotive applications, heavy wall square tubing is used in rail transport, where its strength is needed to ensure the stability and durability of railcars and related infrastructure.

Energy and Utilities In industries such as oil, gas, and renewable energy, heavy wall square tubing plays a critical role in transporting fluids, gases, and other materials. It is used in pipelines, pressure vessels, and other critical systems where strength, durability, and resistance to extreme temperatures are required. The tubing's ability to withstand high-pressure environments makes it ideal for these high-risk sectors.

Marine and Offshore Applications The marine industry also relies heavily on heavy wall square tubing for creating frames, support structures, and other essential components for ships and offshore platforms. Given the challenging environmental conditions that marine structures must endure, the corrosion resistance and durability of heavy wall square tubing make it a critical material for these applications.

Agriculture In agricultural equipment, heavy wall square tubing is commonly used in the construction of frames for tractors, harvesters, and other farming machinery. The ability of the tubing to handle heavy loads while withstanding the rough conditions of agricultural environments makes it a go-to choice for agricultural machinery manufacturers.

From Design to Implementation: How Ailipu Ensures Precision and Quality

While industries rely on robust materials like heavy wall square tubing for their construction and manufacturing needs, precision and quality control are just as important. Ailipu, though primarily known for being a professional USB camera manufacturer, shares the same commitment to excellence in design and engineering. Whether it's cameras or components used in construction, the focus on precision and quality is a driving force behind success.

By applying the same rigorous standards to their USB cameras, Ailipu has built a reputation for delivering high-performance, reliable solutions to industries that demand excellence. This attention to detail, precision in design, and commitment to reliability translate well across any product—whether it's a camera or a structural material like heavy wall square tubing.

Conclusion

Heavy wall square tubing is a cornerstone material in industries where strength, durability, and safety are paramount. Its versatile applications range from construction and manufacturing to automotive, energy, and even agriculture. As industries continue to innovate and evolve, the demand for reliable, high-performance materials like heavy wall square tubing will only increase.

While the manufacturing of tubing might seem unrelated to the world of USB cameras, both require precision, quality, and durability to ensure optimal performance in their respective fields. Whether designing structures for buildings or developing high-performance cameras, the focus on quality and adaptability remains the same.

Understanding the Benefits of Heavy Wall Square Tubing in Heavy-Duty Applications