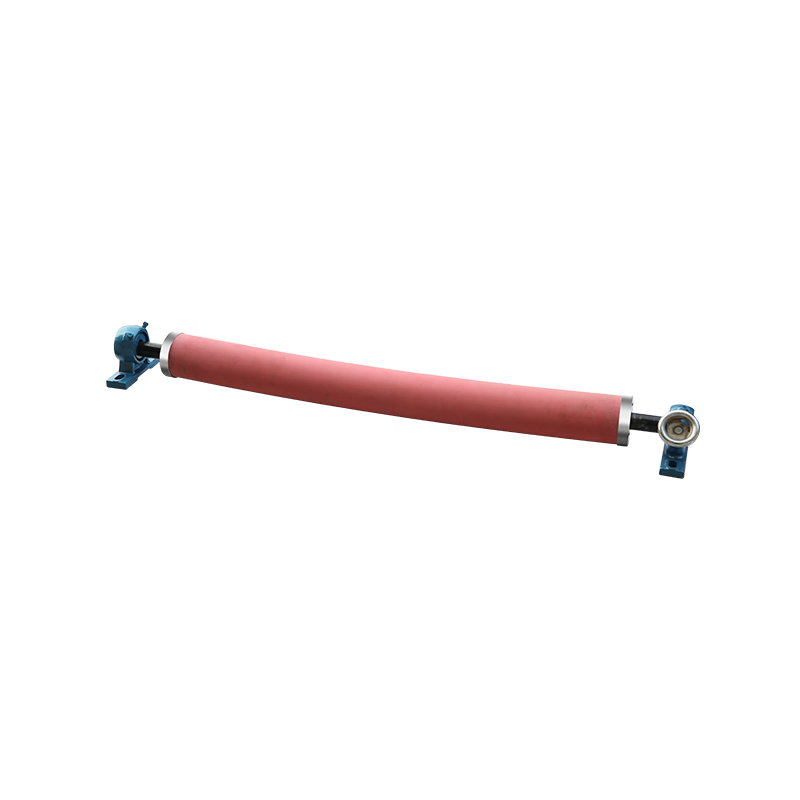

Banana rollers are more than just functional components—they are key to improving production efficiency in a variety of industrial settings. The Banana Roller Design influences the speed and smoothness of the manufacturing process, ultimately impacting throughput.

In industries such as printing and packaging, where large volumes of material are handled daily, the smooth operation of banana rollers ensures that production lines run without unnecessary interruptions. The curved surface of the roller reduces friction and improves material handling, allowing for faster processing times.

Additionally, the precise engineering of banana rollers ensures that materials are aligned correctly, which helps prevent jams and other disruptions. With fewer stoppages and less downtime, manufacturers can increase the overall efficiency of their production lines, leading to reduced costs and higher output.

The continuous development of banana roller designs, including the integration of advanced materials and technologies, has further enhanced their performance. As industries demand higher speeds and greater precision, the role of banana rollers in streamlining production processes becomes even more crucial.

https://www.cbbmachine.com/product/banana-roller/customizable-banana-roller.html

| Number | L1 | L2 | L3 | Applicable base material width |

| 1 | 590 | 678 | 730 | 500mm |

| 2 | 725 | 830 | 880 | 600mm |

| 3 | 1175 | 1265 | 1315 | 1100mm |

| 4 | 1220 | 1278 | 1330 | 1100mm |

| 5 | 1500 | 1560 | 1610 | 1320mm |

| 6 | 1435 | 1488 | 1540 | 1320mm |

| 7 | 1760 | 1810 | 1870 | 1600mm |

| 8 | 1805 | 1828 | 1880 | 1600mm |